Introduction

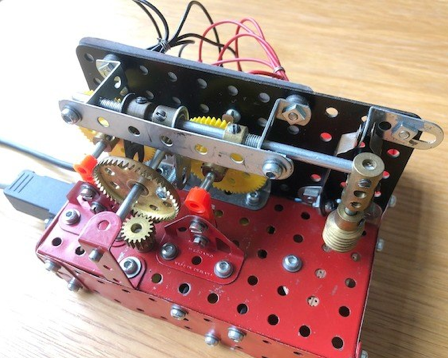

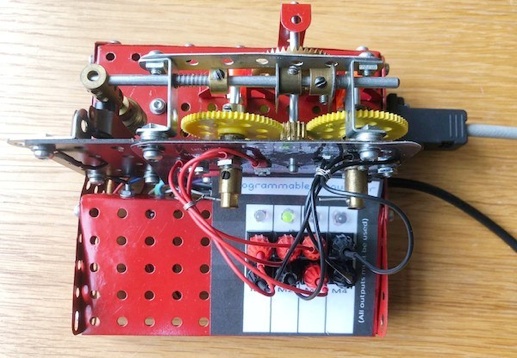

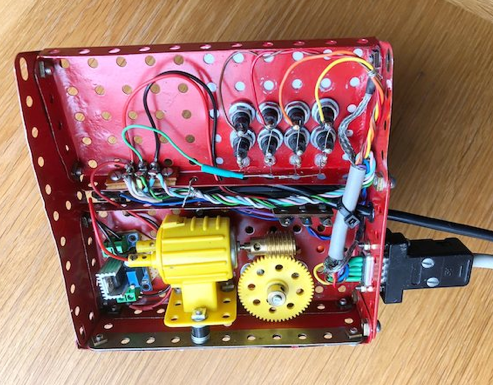

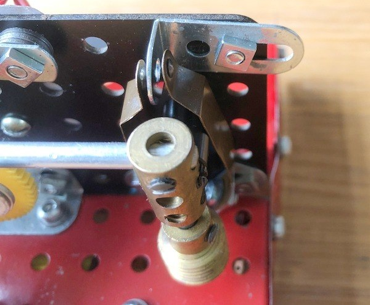

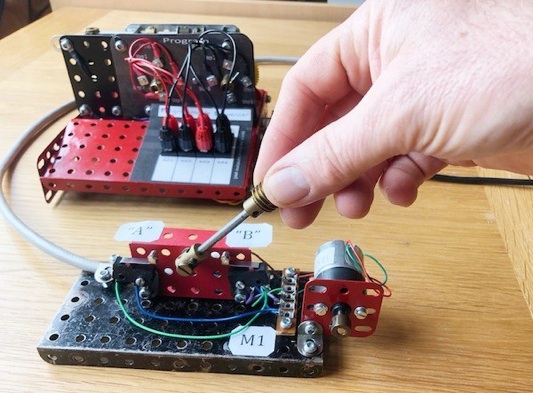

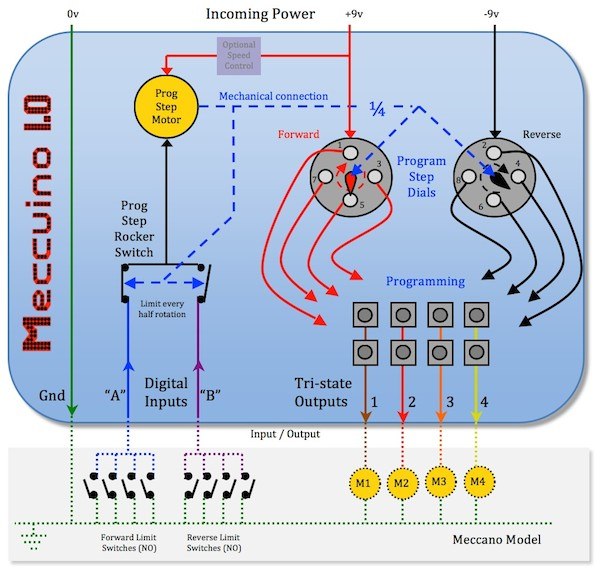

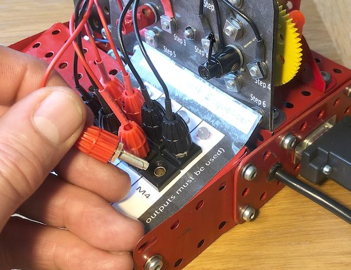

Each analog motor is switched on in whichever direction you choose until it hits a limit. This triggers the next step in your program. As you see it’s made of only a modest number of Meccano parts (although I’ve used a few proprietary connectors and a speed controller for the 2v crane motor) and the design could be extended to: a) have fewer or more steps; b) control fewer or more motors.

There are two tricks if you want to call them that:

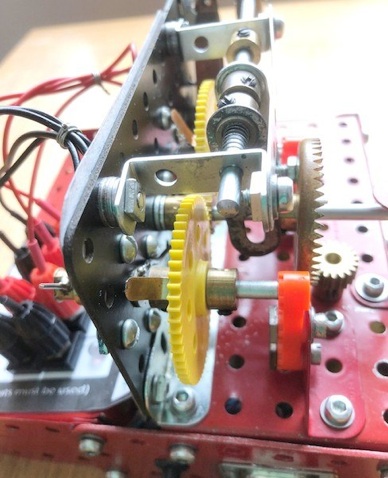

1) the two program step dials are 45° out of phase for an 8 step program. This is achieved by a half rotation of the main shaft divided by a further 4:1 reduction gearing;

2) the motor that drives them is not constantly running but only moves when it has to (that saves power too if you’re an ultragreeny).

If you look carefully I happen to have fitted bicolour LEDs on the Programming board. They show: Red = Forward; Green = Reverse.

(These are not shown on the circuit diagram for clarity and are unnecessary).