Meccano Robotics

& Automation

Meccano Robotics

& Automation

Online Clubs, Ideas, Plan & Components

Disclaimer

Whilst some care has been taken to check externally linked websites no responsibility is offered nor implied for the suitability, legality or reliability of content therein.

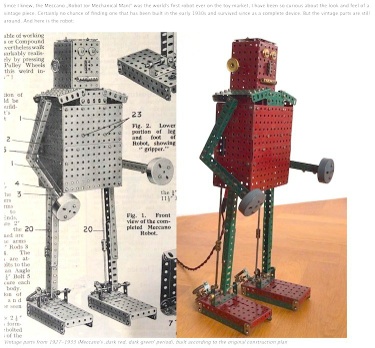

Early Meccano Robots

Meccano robots, in human form, needs no introduction as The Meccano Magazine featured a number of these in the 1930’s. The website Alphadrome claims that Meccano were the first to ever produce a robot toy (near right).

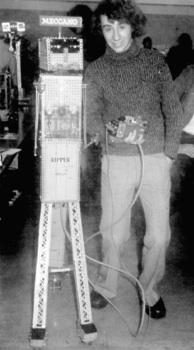

Other designs followed. When I was a teenager in the mid 1970‘s famously I built a number of the more threatening kind -the so called Ripper series of robots. My “De Lux” version was fully lifesized, with visible motorised heart, lungs mouth, Meccano sign and limbs (far right).

Some years before this my group of friends built fighting robots based upon the berserk Venus Probe shown in an episode of the popular Six Million Dollar Man TV series.

Clubs & Ideas

A lot of ideas for bots in a picture gallery. Some really powerful beasts in here..

Components

A good array of mechanical and electronic parts. I’ve used them for years..

Early Meccano Automation

This depends on what your definition of automation is. One might consider the changing sequences of bells in a clock striking mechanism ‘automatic’. One might consider a loom making changing patterns or the interaction of rotating discs in a differential analyser or the carry forward parts of a Babbage calculating machine ‘automatic’. These have each been the subject of models (see bottom of Meccano page).

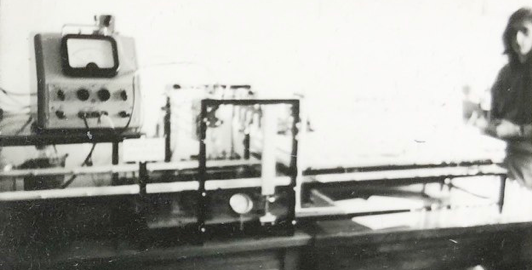

One of the earliest complex Meccano automatic machines that I know was built by my father in a laboratory in 1960’s. Sadly I’ve never found any pictures of the complete machine yet. It was very large (and I was very small when it was built). The main table was a foot wide by several feet long. On a moveable trolley were placed several hundred test tubes containing soil samples taken from a 3D grid in farmer’s large field. It was controlled by a mixture of cams for timing and limit switches and performed chemical analysis on each one. The tests were sensitive enough to analyse microscopic concentrations of nutrients, fertiliser & oxygen levels. When plotted against geography scientists were able to discover the losses of fertiliser run off and thus the causes of the variability of crop growth.

Electronics amplified and scaled the results which were output to an analogue-to-digital converter and then a very early computer was triggered to record a sequence number and the value. It ran for years and the beast was shown at the anniversary of the setting up of the National Vegetable Research Station in Wellesbourne (now run by the University Of Warwick). The Duke Of Edinburgh’s fascination with it hit the local newspapers (I have this article somewhere).

Early Examples In Meccano

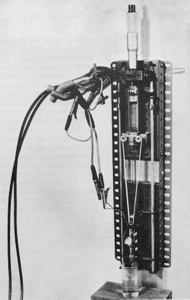

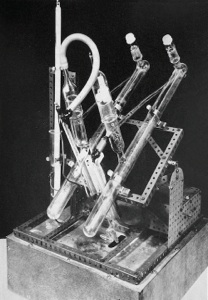

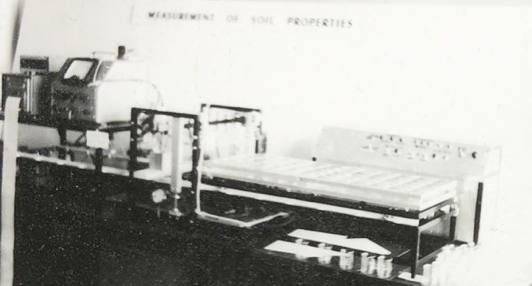

Laboratory nutrient and bacterial gas analysis equipment - the forerunners to complete automation by DGoodman 1959 (from book by BN Love)

Modern Examples In Meccano

Spykee

In 2008 the current owners of Meccano, SpinMaster, launched the Spykee robot. It had a camera, microphone loudspeaker, motorised movements and communicated with computer based software via Wifi. It was an immediate success

(click the photo to see a detailed review of it working).

Meccanoid

In 2012 SpinMaster, launched a completely new and more capable series of robots. The top of the range Meccanoids boasted 6 motors with realistic movements, eyes programmable in 500 colours and for the first time Voice Recognition. They had a language of some 3000 words, phrases and robot related stories ! Standing 600mm high they sold well. The motors all featured optical encoders so could be both programmed via a phone or computer app or learn by being pushed into their various positions. The code was ‘open source’. (click the photo to see a detailed review of it working).

MODERN AUTOMATION (without computers)

Because from very early days Meccano was motorised in some ways automation is what many Meccano models just naturally do. My Road Construction Site features a number of motorised models that follow a number of mechanical sequences that make them look like they are being operated properly.

Plans

MW Mail order carry every conceivable model plan sorted by category or plan number.

Model Plan 60 (see MWMO below) describes a paper folding machine. In 2017 Laurent Chaté upgraded the idea to take sheets of paper, fold them into planes then launch them (click the photo to see it working).

Way back in 1992 the King Of Mechanical Automation, my good friend Chris Shute, produced a machine for taking a matchbox, putting a ball in it, moving it around and emptying it then sending the matchbox back to the start (below left). It’s an intriguing machine to watch (click the photo to see it working).

As most of us know at most Meccano exhibitions there are many automated novelties on display. Skeggex (above right) is a good example (click the photo to see them working).

However for me the most beautiful of non-computer automation is the story told by Chris’s wonderful Wem Treacle Mine (below left). Child or adult you will be mesmerised by the clever detail that he has build in. The rear of the machine only helps you understand a fraction of how it’s done. Timing is achieved by the closed loop feedback from every movement triggering the next stud on an all Meccano sequencer. The only non-Meccano parts are the silent running old cassette motors used to drive each of the six miniature wonderful scenes. See how this works on the next page: Meccano Sequencers (click the photo below left to see it working).

MODERN AUTOMATION (with computers)

It’s all very well to stick to purely Meccano parts and to stick to pure sequences of operations however if one chooses to:

•use some form of computer control, be that a domestic computer, an industrial controller or a tiny Arduino or Raspberry Pi microcontroller

•standard dc motors, stepper motors or linear actuators

•feedback by switch, potentiometer, optical encoder, Hall Effect sensor or optical object recognition

the possibilities become endless. You have a huge range of choices and costs. Do realise how much time and money you could spend and how obsessive you may become as a result of trying to get such a system to work. My suggestion is not to reinvent the wheel but to peruse as many websites as possible and better still contact a helpful club. As a taster here are some ideas..

Computer Controlled Industrial Robot Arm

Stuart Wightman’s servo controlled arm assembles a car. The second half shows it placing seven bricks, with the letters Meccano written on, in an arc. Then moves them into a tower. Then picks the tower up and shows it to an imaginary audience - all very very smoothly. Well done Stuart (click the photo to see it working).

Rubiks Cube Solver

Many solvers have been built over the years. They are all quite surprising to see in operation for the first time. I think it’s rather clever to use just one gripper hand to do this (eg Dave Collins). However by using three hands Paul van de Veen has made this extremely efficient high speed solver. (click the photo to see it working).

These pre-dated BBC’s Robot Wars by at least 20 years and the children’s toy by 2 years. The idea was to inflict as much destruction on your opponents Meccano model as possible so jaws and a chopper weapon were all part of the difficulty of fitting everything into a small space - like real robots really.. (alas there are no photos of our models that I know of).

MECCANO AUTOMATIC WORKSHOP EQUIPMENT

I have long wanted to make compatible non-standard Meccano parts and for decades others have turned (excuse the pun) their workshop skills to that end to feed a hungry market. However producing more than a small run is expensive unless you have the right NC equipment. But Meccano’s up to the job - it always is..

Meccano Lathe

André Theberge has proved that a compact perfectly operational lathe can be built to turn out Meccano gears. He uses a pretty powerful motor to machine brass and the small size makes for accurate workmanship. The laptop computer takes care of the rest.

As you probably know the father of our favourite hobby made some pretty wise decisions when he devised our system. However, until you think about it, one realises that because all Meccano gears have the same tooth pitch (38DP with 20º PA) Meccano themselves only needed one size tooth cutter for all sizes of gears (except those of the giant roller bearing). Well done again, Frank. (click the photo to see it working)

Meccano 3D Printer

In my humble opinion it is 3D printing that requires the second highest level of skill in Meccano model building and way back in 2014 I was impressed by the late Dave Collins’ 3D Printer (right). On the WLMS stand at The International Model Engineering Exhibition at Alexandra Palace and St Albans Model Engineering Exhibition in that year and subsquently he made Meccano compatible parts right in front of us. That was a first to me. He explained that there are quite a number of software process that need to be executed: the original design he drew in Google SketchUp, this was exported to a compatible 3D modeling format file. This then had to be rotated and scaled to fit on the glass printer table. Then it was translated into internationally agreed 3D printing stepper motor language which he then transferred to a separate microcontroller attached to the table (see foreground).

How could he better that ? Well he then went on to produce use his 3D printer to make more 3D Printer parts. Not only was this the reason why he was everyone’s favourite but he was also such a thoroughly nice bloke !

Close up of André Theberge’s heated 3D printing head. Notice also the heavy current wires for the power to indirectly heat the glass printing table from below.

Since then André Theberge’s skill in Meccano has taken this to another level. His giant Meccano 3D printer (far right) zips round the printer plate (above right). Of course he doesn’t print in metal yet but who knows what he has round the corner ? (click the photo to see it working)

Further Developments

I said second highest level of skill. Well, again IMHO, there is one machine that I have never seen and I personally would find very useful. That is a Meccano 3D Printed Circuit Board milling machine. This is where a PTFE sheet which has copper attached to each side, known as ‘copper clad’, has the gaps between circuit tracks removed by a tiny high speed rotary cutter. Holes, of various sizes, are cut through in many places for electronic components and connectors. The board is then flipped over and more tracks cut in the same way. This procedure avoids the use of all the UV photo etch resist and very nasty etching chemicals. Notice the large blower pipe in the close up (right) to remove swarf from making the edges of the tracks ragged (See GarageLab Milling Advice)

Could we one day even see Meccano lasers cutting the gaps. You heard it here first chaps ! However I assume that boiling copper and PTFE oxides are not best for your lungs ?

Max

In July 2017 SpinMaster, under the Meccano-Erector name, launched a leap beyond any other toy on the market. I would say that it meets, if not overtakes, Alexa in its use of Artificial Intelligence. I say this because it is fully conversational and will learn about objects that you place before it and remember what they mean to you. This is true personalisation. For roughly the equivalent of £140 the lady in the video has actually accepted Max as another member of her family !

(click the photo to see a review of it working).

Gargantua

And finally the pinnacle of non-computer automation is the programmable Gargantua Crane originally designed by ‘Bill” Griffith Taylor of Toronto who, after 3 years work completed when he was only 21yo. Originally published a year later in the Meccano Magazine of March 1938 Chris Shute built a working copy and displayed at the Meccanuity Exhibition in the Enginuity Museum in Ironbridge in 2009. It is completely of Meccano parts except the large counterbalance weight (four housebricks). One single motor drives all operations controlled by holes in a 3½” wide paper tape. (Unfortunately I know of no videos showing it working. Click on photo for CyberneticZoo & Chris Shute historical article).

Dr Michael Adler has made some seminars that I recorded please go to the following page and click Zoom Seminars: Meccano Vaults

There are many more examples at the very bottom of the following page: Meccano.

STOP PRESS - January 2021

I said that I couldn’t find any pictures of my father’s automated analyser. Well amongst some very old Christmas decorations that I unearthed a few weeks ago I found an old 35mm film contact strip and had ignored it until today. The pictures are tiny but I believe that I can just make out the words “Measurement Of Soil Properties”. The bench mounted equipment looks as I remember it so guess that it is his automated analyser. It was the multi-probe automated version of the device in the left picture above.

It can’t be actually running when this is taken because the probes are in their wash area and the whole carousel of samples is on the extreme right - the loading position. Overnight dry soil samples, test tube by test tube, row by row, it would have added a measured amount of distilled water and analyse each one as they travelled to the extreme left. Although it can’t be seen from this view all the guts of it, around the speed frame at the left-hand end, are indeed Meccano motors and gears.

Judging by other pictures on the reel it is about mid 1967. That was a very active year for my father as it’s the same year that the Midlands Meccano Guild was started by him and others (and I got my first Gears Set !)

I have no idea where the negatives are, if they still exist, but I am really rather pleased.

In the meantime do take a look at the following pages: Meccano Sequencers & Microcontrollers.

MODERN ROBOTS

Speedplay

As a precursor to the robot sets Spinmaster introduced this completely new, yet compatible, construction system in 2005. The range of set has grown considerably to the present day.

Don’t forget that one doesn’t have to stick to their ideas you can have an infinite number of your own as Gary Higgins of Auckland Meccano Guild shows so well (below).